Motorcycle automatic clutch E-Clutch motor drive solution

Not long ago, Honda released their new E-Clutch technology on the global website. Judging from the response on social media, it is not surprising that the reviews have been mixed. Most people are positive about this innovation, but some think it may become another electronic "nanny" system.

To better understand what's causing the controversy, it's best to start by explaining the nature of E-Clutch. As Honda describes it, this is an electronically controlled system designed to provide instant, precise clutch control, including starting, shifting and stopping, making it more natural for the rider to operate the clutch manually. What's more worth mentioning is that the regular mechanical clutch operation is still present, so there is an option to turn it off and operate the clutch in the traditional way.

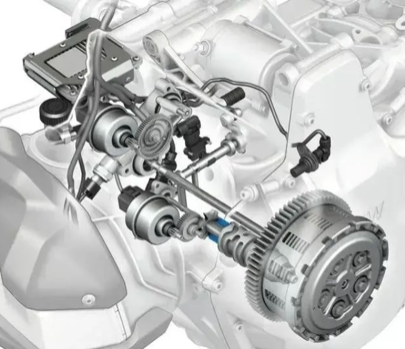

How E-Clutch Works

E-Clutch is mainly composed of electronic control unit (ECU), sensors and actuators. The sensor is responsible for real-time monitoring of various operating parameters of the vehicle, such as engine speed, vehicle speed, gear shift signals, etc., and transmits this information to the ECU. The ECU analyzes and makes judgments based on the received information, and then issues precise control instructions to the actuator. The actuator usually uses a motor or electromagnetic device to control the engagement and separation of the clutch according to the instructions of the ECU, and accurately controls the engagement speed and separation degree of the clutch to achieve optimal power transmission and shifting operations.

Advantages of E-Clutch

Improve driving comfort: E-Clutch can automatically optimize clutch operation, making the shifting process smoother and smoother, reducing the frustration when shifting, especially in urban congested traffic conditions, allowing the driver to avoid frequent clutch operations. Get rid of it and reduce driving fatigue.

Improved control performance: The rapid response capability of the electronic control system enables the clutch to engage and disengage faster, and can more accurately cooperate with the work of the engine and transmission. It can achieve more efficient power transmission when accelerating, decelerating and shifting gears, improving The vehicle's acceleration performance and handling stability provide drivers with a better driving experience.

Enhanced fuel economy: E-Clutch can accurately control the clutch operation according to the vehicle's driving status and engine load, keeping the engine always within the optimal operating speed range, effectively reducing fuel consumption and improving the vehicle's fuel economy.

Easy to integrate and intelligent: As part of the automotive electronic system, E-Clutch is easy to integrate with other electronic systems, such as engine management systems, transmission control systems, etc., to achieve overall intelligent control of the vehicle. It can also be integrated with automatic start-stop technology, The combination of hybrid power systems, etc. further enhances the performance and environmental protection of the vehicle.

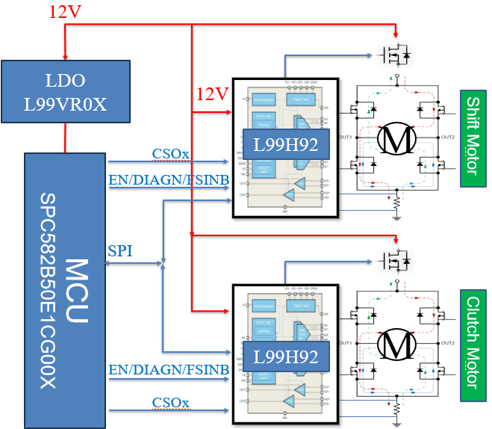

ST E-Clutch Main Solutions and Features:

1. 12 V DC power supply connector

2. Connector for DC motors

3. Current sensing network based on the internal operational amplifier of the L99H92 driver

4. External current sensing network based on the TSC103

5. Fail-safe input negative button

6. RSENSE for the current sensing networks

7. Connector for the L99H92 driver control

8. Connector for the supply of the L99H92 I/Os and current sense amplifier output stage

9. SPI connector

10. Sensing (current sensing and supply sensing) connector

11. L99H92 driver

12. STL285N4F7AG external MOSFET for full-bridge/half-bridge configuration

13. TSC103 operational amplifier for the high-side current sensing

14. External reverse battery protection

Scenario application diagram

Display photos

Solution diagram

Core Technical Advantages

• Up to 50 A motor drive

• Anti-pinch detection via programmable gain current sensing

• In-line, low-side and high-side current sensors

• Alerts the microcontroller in case of fault conditions to avoid periodic on-demand fault checking via SPI, thus ensuring timely intervention of the reverse battery protection dedicated circuit

• Fault detection capabilities:

– Open load, short to ground, thermal alarm and over temperature shutdown

– Under/over voltage protection

– Over current protection

• Low component count

• AutoDevkit ecosystem

Solution Specifications

The L99H92 is a gate driver, which is programmed through a microcontroller. It is designed to drive four external N-channel MOSFET transistors in a single H-bridge or dual independent half-bridge configuration for DC motor control in automotive applications. Moreover, two Independent current sense amplifiers are available, used to detect the current in in-line and low-side parts.

The L99H92 features available in the AEK-MOT-WINH92 are:

• A dual half-bridge driver used to control four external N-channel MOSFET transistors

• Two independent current sense amplifiers

– Independently programmable gain (10x, 20x, 50x, 100x)

– Offset on operational amplifier output centered at VDD/2 or VDD/22

• All the actuator outputs come with the following protection and supervisor features:

– Current monitoring (in-line and low side only)

– Open-load, short-to-ground, and short-to-battery conditions

– Thermal warning and overtemperature shutdown

– Under/overvoltage protections

– Overcurrent protection

– Charge pump monitoring

• Charge pump output available for driving an external reverse battery MOSFET protection

• Asynchronous and logic independent fail-safe input to switch off all the MOSFETs

• DIAGN output pin, which is faster than SPI communication, to alert the microcontroller of a fault occurred in the device

• Configurable window watchdog